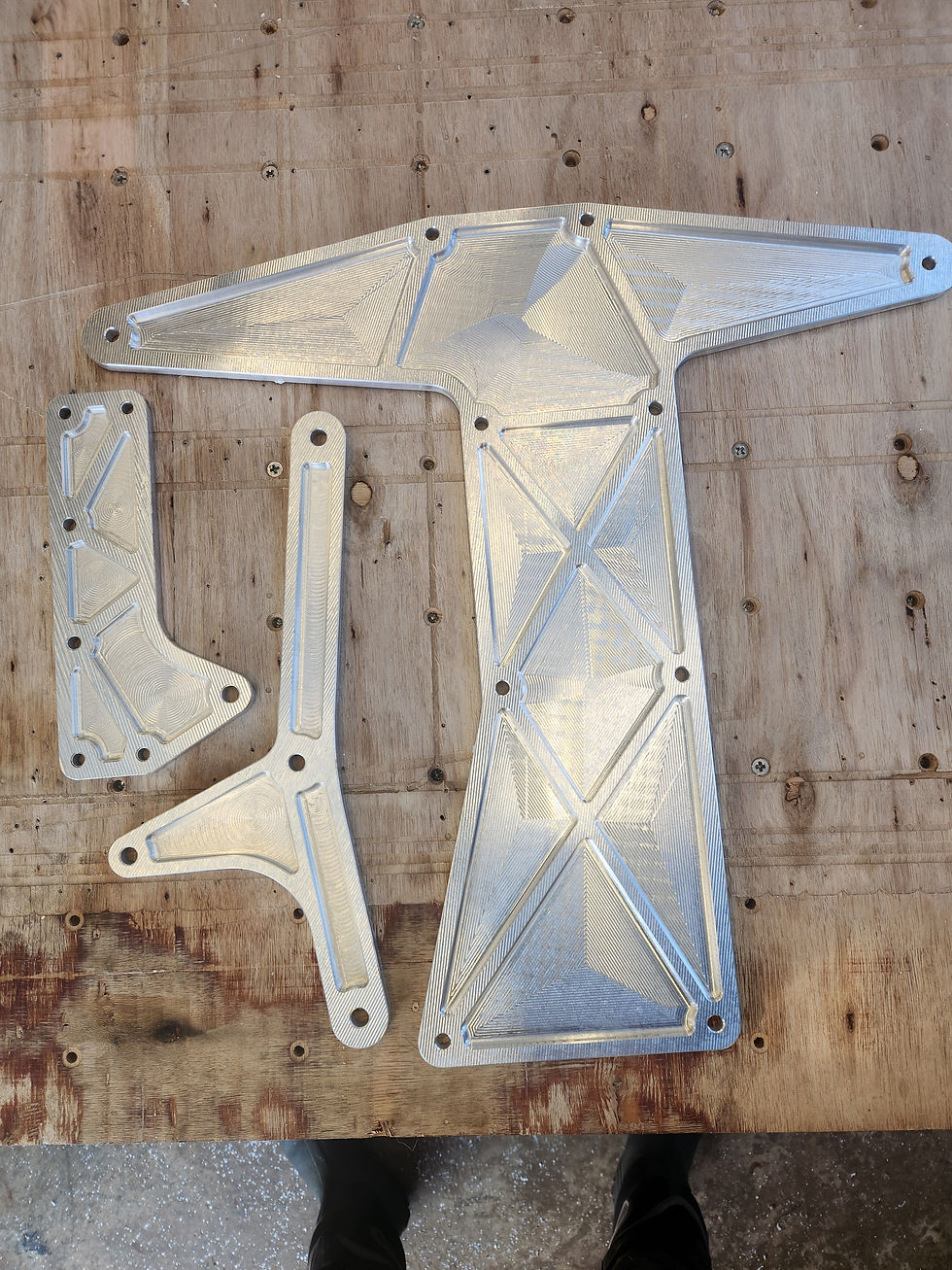

Hi All, has anyone had issues with the spindle on their MetalStorm? My machine seems to have picked up a bad vibration all of a sudden and leaving deep grooves when facing. I have tried tramming the spindle to the bed to correct the grooves but the vibration is steadily getting worse. I have been good results machining aluminium last week with, 1F 4mm UC & 1F 8mm UP bits as well as 30deg 1mm engraving bit, but all of a sudden I cannot get a flat surface at all. Before I start stripping my spindle or ordering a new one, has anyone experienced this before? Below are the finishes that are actually very flat and smooth, even though it does look rough. The 4mm bit leaves a lot of pass marks but the surface is very flat:

These are the finishes Im getting now:

I believe that I have the 1st MetalStorm delivered to a customer so what is currently being offered may differ slightly from mine. I will contact Dave directly as well, but in the past he has suggested using the forum for trouble shooting issues since there is a wealth of knowledge out there. I have: - Changed bits, new out of the packet and used. - Changed bit sizes from 4mm to 8mm 1FUC & 19mm facing bit. - Changed feed rates - Changed depth of cuts - Cleaned & re-Lubed all slides and screwfeeds - Trammed the spindle

There is a noticeable change in the spindle noise frequency when running at idle and during a cut from last week. The spindle rotates fine by hand and no noticeable free-play. The machine has NOT been crashed at any point. Maximum plunge feed rates with Aluminium has been 150mm/min Any thoughts?

This has been relied to via email. :)