Making a better customer experience

- CNC3D

- Jul 1, 2019

- 1 min read

Finally!

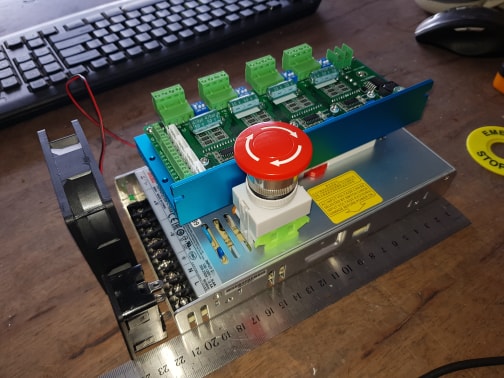

After 42 hours of 3D printing our first enclosure prototype fit perfectly. It's not very often these things happen first go so we're quite impressed with ourselves.

The next step now is to add our new custom SharpCNC controller board with the rest of the inputs and outputs (probe, coolant, door, limit switches, spindle direction) and then reprint the main enclosure all over again.

If all goes well It's off to the injection moulder to mass produce them so we can send them off to our SharpCNC customers.

Comments